- [email protected]

- +86-21-63353309

sag mill operation

sag mill operation

Influence of feed size on AG / SAG mill performance

2001/1/1 · However, as exemplified in this paper, the Strategic and Tactical Mine-to-Mill aims at real-time re-scale of mining and processing activities for optimal outcomes in response to large uncertainties

Learn MoreSAG Mill Grinding Circuit Design - Mineral Processing & Metallurgy

SAG mill operation is more dynamic, and typically requires a higher degree of process control sophistication. Though more complex in AG/ SAG circuits relative to the crushing plants they have largely replaced, these issues are well understood in contemporary applications.

Learn MoreSAG mill Optimisation and increasing throughput at the Phu Kham Copper-Gold Operation

8/30 · Mill Operators SAG mill Optimisation and increasing throughput at the Phu Kham Copper-Gold Operation – a success story This product is exclusive to Digital library subscription Subscribe SAG mill Optimisation and increasing

Learn Moresunshine 5233: sag mill operation

A SAG mill is usually employed like a primary or initially stage grinding remedy The SAG mills make use of the nominal ball charge of 6 to 15%. SAG mills could be as massive as 42" across, with as numerous like a 28 MW motor.

Learn MoreOperation Analysis of a SAG Mill under Different Conditions

operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the breakage process of the

Learn MoreSAG Mill Process Control - Grinding & Classification Circuits

The purpose of a grinding mill is to convert electrical energy into rock breakage. The best use of that asset is to try to maximize the power draw. Try to hold the mill speed high and vary the feed rate to hold the weight (or bearing pressure), but watch out for "cycling" or "surging" that indicates instability in the charge.

Learn Moresag mill operation list - sag mill operation for sale

We doesn't provide sag mill operation products or service, please contact them directly and verify their companies info carefully. Total 9882 products from sag mill operation Manufactures & Suppliers

Learn Moreimproving energy efficiency via optimized charge

Operation of SAG Mills. 5. 1.1.1 Field of breakage. 6. 1.1.2 Flow through the grate and pulp lifters. 7. 1.1.3 Charge motion. 7. 1.1.4 Mill power draft.

Learn MoreContinuous improvement in SAG mill liner design using new

Implementation of the new design in the SAG mill was carried out, resulting in increase in daily throughput from 6 to 12%. Further, the time spent in liner change was reduced by 47% given the

Learn MoreCONTROL AND OPERATION OF SAG MILL - Encuentro Metalurgia

Influence of ore variability on mill and circuit design. Ore Breakage Characterisation information for circuit, crusher and mill design. Collecting and Using survey data for Circuit design. Discussion on surveying plants. Insights into grinding action in mills. SAG mill operation. Feed preparation - putting particles in the wrong sizes during

Learn MoreComminution Circuit Design vs. Feed Size or 'Mine to Mill 2.0

current SAG mill operating conditions. – not setup for coarse material secondary crushed feed. – eliminate +100mm particles (P.

Learn MoreFile:Principle of SAG Mill operation.jpg - Wikimedia Commons

File:Principle of SAG Mill operation.jpg No higher resolution available. Principle_of_SAG_Mill_operation.jpg (566 × 464 pixels, file size: 38

Learn MoreIncrease throughput and capacity in SAG mills

SAG mills are the main workhorses in the majority of comminution circuits globally. They need to be fed and kept working round the clock. But challenges can arise when capacity is not optimised causing unnecessary downtime and liner wear leading to the one sound operators do not want to hear - the sound of the mills standing still.

Learn MoreSemi Autogenous Grinding Mill - an overview

7 [1]. Size reduction occurs through a primary crusher followed by semi-autogenous grinding (SAG). Large rocks are screened from the overflow and are sent

Learn MoreCONTROL AND OPERATION OF SAG MILL - PEBBLE CRUSHING CIRCUITS

SAG mill operation Feed preparation - putting particles in the wrong sizes during crushing Discussion on Feed Preparation Principles of Crusher operation Discussion on the purpose and needs of process control Process control, Lag time for feed rate and load interaction, grindcurves Controlling the Dynamic Behaviour of the Mill

Learn MoreEnergies | Free Full-Text | Operation Analysis of a SAG Mill under

As one of the machines widely used in mining, a semi-autogenous grinding (SAG) mill can significantly improve the roughing efficiency of rock. But the SAG mill still faces the obstacles of significant energy consumption and empirical operation parameters. In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the

Learn MorePDF EXPERIENCES IN SAG MILL OPERATION - intermetperu.comPDF

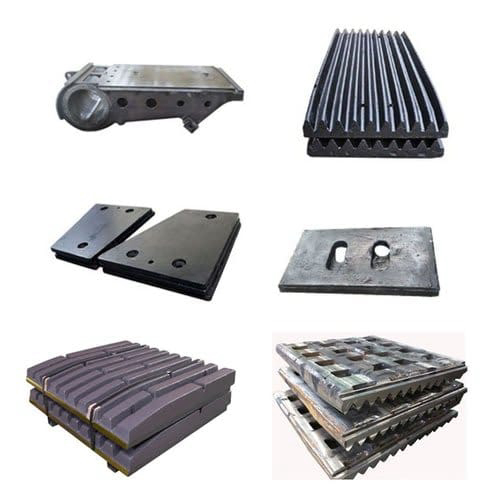

Describe in detail SAG mill circuits of large-scale plants and the benefits of each. - Detail the issues occurred during SAG mill operation: blockage of grates, cracking of bolts, liners and grates, flowback, carry over; blockage and breakage of meshes from trommel and screen, among other relevant issues.

Learn MoreBrainWave: Control solutions for SAG mills

operation due to changes in ore hardness over time. With improved SAG mill control stability, the mill load can be optimized to.

Learn MoreSAG Mill Optimisation and Increasing Throughput at the Phu Kham Copper

The Phu Kham Operation has recently undergone a series of process improvements to treat the anticipated competent ores scheduled for and 2018. The operation's comminution circuit, which comprises a semiautogenous (SAG) mill and two ball mills, each with 13 megawatts (MW) of installed power, was expected to be SAG mill limited when

Learn MoreSAG MILLING IN AUSTRALIA – FOCUS ON THE FUTURE

The drive for low operating cost has seen the retention of fully autogenous circuits in some large installations, notably Olympic Dam. ISSUES IN MILL AND

Learn MoreSAG Mill Optimization using Model Predictive Control

Model predictive control provides an additional tool to improve the control of Semi-Autogenous Grinding mills and is often able to reduce process variability

Learn MorePAI SAG Mill Training

1/8 · In this training module, we'll cover the workings of a semi-autogenous grinding mill, or SAG mill, that's designed to be the first stage of a grinding circuit. Ore that’s crushed in a

Learn MoreSAG Mill Grinding Circuit Design - 911 Metallurgist

SAG mill operation is more dynamic, and typically requires a higher degree of process control

Learn MoreSales Operations Supervisor Job Hillsboro Oregon USA,Sales

Sales Operations Supervisor. Job in Hillsboro - Washington County - OR Oregon - USA , 97123. Company: Pape' Kenworth. Full Time position. Listed on 2022-09-15. Job specializations: Sales. Area Manager, Sales Manager, Sales Associate.

Learn MoreOptimizing your SAG mill operation - International Mining

2007/3/21 · • Allow the mill to operate at maximum capacity • Ensure good grinding conditions with lower grinding energy per tonne • Efficient operation even at higher mill

Learn MoreSemi Autogenius Grinding (SAG) Mill

The SAG mill is often one of the largest pieces of mining equipment and is key for operations. Often used in the mining process of precious metals, the SAG

Learn More