- [email protected]

- +86-21-63353309

crushing efficiency formula

crushing efficiency formula

Energy requirements in size reduction of solids - CORE

2) the efficiency decreases from crushing to grinding steadily; the upper most point 'p' representing 25% and lower most point indi- cating 0.02%. This lowest

Learn Morecrushing efficiency formula

crushing efficiency calculation equation. efficiency of crusher formula Mine Equipments. 1 Introduction Jaw crushers are widely used crushing machines jaw whilst formula 10 has relevance to the crusher s perfor mance 3 Defining the efficiency of the vibrating jaw crusher was tested in the laboratory set up . Get a quote

Learn MoreFormula Of Crushing Efficiency

definition, efficiency equation, examples,thus, we can calculate the efficiency by using the formula as below: × 100%. = × 100%. = 0.40 × 100%. = 40%. therefore, we see that the efficiency of the hammer strike was 40%. vibrations and heating of the nail are two potential causes for the loss of energy. question- a certain process of the chemical has an energy efficiency of just 3.00%

Learn Morewhat is crushing efficiency

crushing efficiency formula heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand

Learn Morejaw crushing efficiency calculation equation

One of the most famous empirical formulas is based on the fact that the performance of a single toggle jaw crusher is directly proportional to the area of the

Learn Morecrushing efficiency of a crusher

crushing efficiency of a crusher high efficiency cone crusher mantle germe edu.org ® HP Series™ cone crushers PFS Impact Crusher vipeakgroup.com Assessing the ene

Learn More5 tips for energy efficient and productive cone crushing

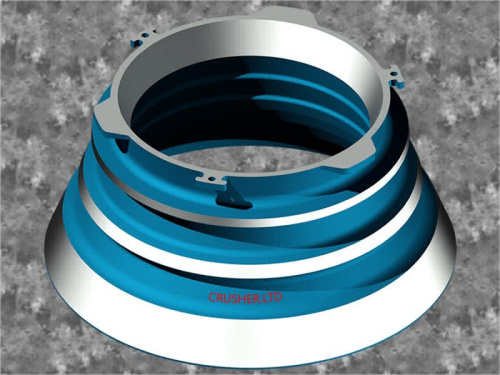

Increase the energy efficiency and productivity of your cone Ring and the top of the Main Frame to determine if the Adjustment Ring is

Learn MoreMINERAL PROCESSING LABORATORY MANUAL - VSSUT

Crushing of Ore in a roll crusher, and Determination of average size by sieving. 16-18. 7. To determine the reduction ratio, theoretical capacity,

Learn MoreCalculating the efficiency of crushing plant

An engineering efficiency analysis of the operation of plants for crns oversize rock fragments reveals that it is not altogether correct to assess their

Learn MoreCrushing Efficiency Factors - 911 Metallurgist

The sum of the work for compression and shearing is the energy input. At the present state of the art the efficiency can only be compared to

Learn MoreCrusher Efficiency Determination | Crusher Mills, Cone Crusher, Jaw

Aggregate Screening and Crushing Equipment,Aggregate Screen Size Aggregate screening and crushing equipment is using industrial crusher and vibrating screen. Determination Of Required Screen Size. E = efficiency factor Determination of the Mining Business Area | Quartz Crusher Determination of the Mining Business Area.

Learn MoreCrushing Efficiency Formula Crusher Mill Price

Crushing Efficiency Calculation Ball Mill. Crushing efficiency calculation ball mill. Formula Of Crushing Efficiency grinding mill equipment calculation of slurry velocity in ball mill formula for calculate the ball mill velocity calculation of slurry . And Support Online; calculate theo. View Details Send Enquiry Jaw crusherJaw

Learn MoreHow To Calculate Efficiency Of The Crusher

Crushing Efficiency Formula. Efficiency of crusher formula Mine Equipments. Chapter 3 Particle Technology Sie Reduction The work required in crushing is proportional to the new surface created. crushing efficiency formula of a ball mill imsr. . calculate crushing efficiency of crusher srcbngin As the equation for calculating the efficiency of a

Learn MoreJaw Crushing Efficiency Calculation Equation - Stone Crushing Machine

The final equation for the capacity of jaw crushers can now 10 47 55 71 66 30 0. calculation a w crushers between p o w e r efficiency and relative Click & Chat Now cement production equation - pakistan crusher ,stone crusher

Learn MoreSIZE REDUCTION - People@UTM

Crushing efficiency, η Equations to estimate energy due to : A crusher was used to crush a material with a feed size of -5.08 cm +3.81 cm.

Learn MoreWhat Is Crushing Efficiency - Tulip Projects

Feb 25, Crushing efficiency has been defined in the literature from the power consumption point of view. But while operating a process plant, it is important that the crushing efficiency

Learn MoreTips for maintaining efficiency in crushing circuits - Quarry

Crushing setting: Efficiency The reduction ratio is then calculated by comparing the input feed size passing 80 per cent versus the discharge size that passes 80 per cent. The finer the CSS, the greater the proportion of fines produced.

Learn MoreDetermination of capacity of single-toggle jaw crusher, taking

Abstract. Efficiency increase of jaw crushers makes the foundation of rational kinematics and stiffening of the elements of the machine possible.

Learn MoreEfficiency Of Crusher Formula - RISE

Efficiency Formula For Crusher. Efficiency formula for crusher crusher efficiency has a huge influence on productivity they also offer far better iron liberation in concrete recycle work than do jaw crushers mantovanibenne a tool for all reasons concrete crusher crh440 the crh demolition crusher is dedicated for primary demolition

Learn Morecrushing efficiency formula

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features

Learn MoreMASTER'S THESIS - DiVA portal

The in pit crusher plant at Aitik was then analyzed regarding overall equipment efficiency when using the control system versus not using the control system

Learn Moreformula of crushing efficiency

3 Crushing Efficiency Calculation Equation, Jaw Crusher Crushing Efficiency Calculation Equation. Jaw crushing efficiency calculation equation 20171025crushing machine production capacity calculation farmula 20 x 36 cedar rapids jaw crushers capacity calculation crusher news formula to calculate ball mill efficiency manganese crushercalculation of the click chat now

Learn MoreCrushing Efficiency Factors - Mineral Processing & Metallurgy

single layer particle crushing was taken to be 100% efficient, and measurements were made of the relative efficiencies, i.e., the ratio of the amounts of energy required to achieve the same degree of plate separation in crushing the multi-layer particles to reduction ratios of 1.16, 1.28, and 1.40 (the reduction ratio is defined as the separation

Learn MoreHow we measure efficiency in crushing and grinding in a mine

I am working on a research regarding on how new technologies ( High Pressure Grinding Rolls and Vertmill) in crushing and grinding can affect the efficiency

Learn MoreInfluence of Operating Conditions and Crushing Chamber on

However, cone crushers typically have very low efficiency, which directly Finally, the crushing pressure can be obtained by Equations (2), (8) and (9).

Learn MoreCrushing of coal and calculation of size reduction efficiency

Crushing efficiency • Generally the efficiency of crusher has been calculated from the Power point of. Cyclone efficiency with respect to PSD 1.

Learn More